ACAR 1200 MCM

ACAR 1200 MCM Aluminium Alloy Greased Conductor for 500kV Transmission Line

ACAR - Aluminium Conductor Alloy Reinforced (KCMIL Series) products

Description:

Cable ACAR Application:

ACAR is used as bare cable for overhead transmission and distribution lines and also as bus-bar in substations where is highly suitable considering the mechanical and electrical characteristics. As comparison with ACSR of same weight, ACAR can offers higher ampacity and mechanical strength.

ACAR 1200 MCM Especificación

B.1 | Conductor type |

| ACAR | ACAR |

B.2 | Code name |

| ACAR 1200 MCM 30/7 | ACAR 1200 MCM 30/7 |

B.3 | Standards that fulfill |

| ASTM B-524 | ASTM B-524 |

B.4 | Cross section area | mm2 | 608.05 | 608.05(nominal) |

B.5 | Nominal external diameter | mm | 32.02 | 32.02 |

B.6 | Nominal unit weight | kg/m | 1.676 | 1.676 |

B.7 | Minimum breaking strength | kg | 1,182 | 1182 |

B.8 | Number of aluminum wires 1350 - H19 | each | 30 | 30 |

B.9 | Number of aluminum alloy wires 6201-T81 | each | 7 | 7 |

B.10 | Final elasticity module | kg/mm2 | indicate | 5700 |

B.11 | Linear expansion coefficient | 1/ºC | indicate | 23.0×10-6 |

B.12 | A.C. Electrical resistance , 50 Hz at 25ºC | Ohm/km | indicate | ≤0.0512 |

B.13 | Wiring direction |

| RIGHT | RIGHT |

C | WIRE OF ALUMINUM ALLOY 6201 - T81 |

|

|

|

C.1 | Standards that fulfill |

| ASTM B-398 | ASTM B-398 |

C.2 | Nominal diameter | mm | 4.574 | 4.58 |

C.3 | Minimum conductivity at 20ºC | %IAC | indicate | 52.5 |

C.4 | Minimum average breaking strength |

|

|

|

C.4.1 | - Before wiring | MPa | indicate | 315 |

C.4.2 | - After wiring | MPa | indicate | 302 |

C.5 | Minimum average elongation in 254 mm |

|

|

|

C.5.1 | - Before wiring | % | indicate | 3.0 |

C.5.2 | - After wiring | % | indicate | NA |

C.6 | Type of welding and welding wire treatment |

| indicate | cold-pressure welds or cold-upset welds |

C.7 | Minimum tensile strength on welded wire | MPa | indicate | 290 |

C.8 | Coefficient of linear expansion | 1/ºC | indicate | 23.0×10-6 |

D | WIRES OF ALUMINUM 1350 - H19 |

|

|

|

D.1 | Standards that fulfill |

| ASTM B 230 | ASTM B 230 |

D.2 | Nominal diameter | mm | 4.57 | 4.58 |

D.3 | Minimum conductivity at 20ºC | %IAC | indicate | 61.0 |

D.4 | Minimum average breaking strength |

|

|

|

D.4.1 | - Before wiring | MPa | indicate | 165 |

D.4.2 | - After wiring | MPa | indicate | 153 |

D.5 | Minimum average elongation in 254 mm |

|

|

|

D.5.1 | - Before wiring | % | indicate | 2.1 |

D.5.2 | - After wiring | % | indicate | NA |

D.6 | Type of welding and welding wire treatment |

| indicate | cold-pressure welds or cold-upset welds |

D.7 | Minimum tensile strength on welded wire | MPa | indicate | 145 |

D.8 | Coefficient of linear expansion | 1/ºC | indicate | 23.0×10-6 |

E | REELS |

|

|

|

E.1 | Nominal length of conductor strip | m | >= 2,000 | 2,000 |

E.2 | Gross spool weight including conductor and lathing | kg | indicate | 3452 |

E.3 | Outer Diameter on lathing | cm | indicate | 110 |

E.4 | Diameter of the flange (flange) | cm | indicate | 220 |

E.5 | Diameter of the drum | cm | indicate | 220 |

E.6 | Inside width between flanges (flanges) | cm | indicate | 94 |

E.7 | Outside Width | cm | indicate | 110 |

E.8 | Diameter of the hole for the shaft | cm | indicate | 12.5 |

E.9 | Number of bolts (tensioners) of flanges (flanges) | each | indicate | 8 |

E.10 | Material from which the reel is made | each | Metallic | steel-wooden |

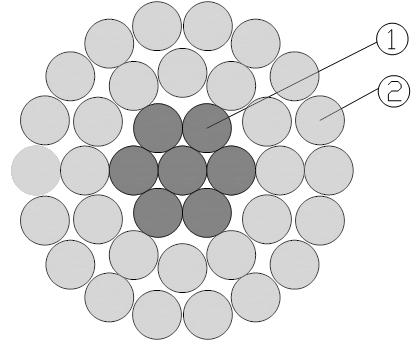

Estructura del conductor

ACAR 1200 MCM

Construction | NO./ Nominal Diameter(mm) | Nominal Diameter(mm) |

1--- Aluminum-Alloy wire | 7/4.58 | 13.7 |

2--- Aluminum wire | 30/4.58 | 30.02 |